Dual-Color, Dichromatic 3D Printing Filament

Check out the Dual-Color Filament Deals (Affiliate)

Mystic Silky by Redline Filament (GERMANY)

magicPLA by 3DJake (EUROPE)

Quantum PLA by Matterhackers (USA)

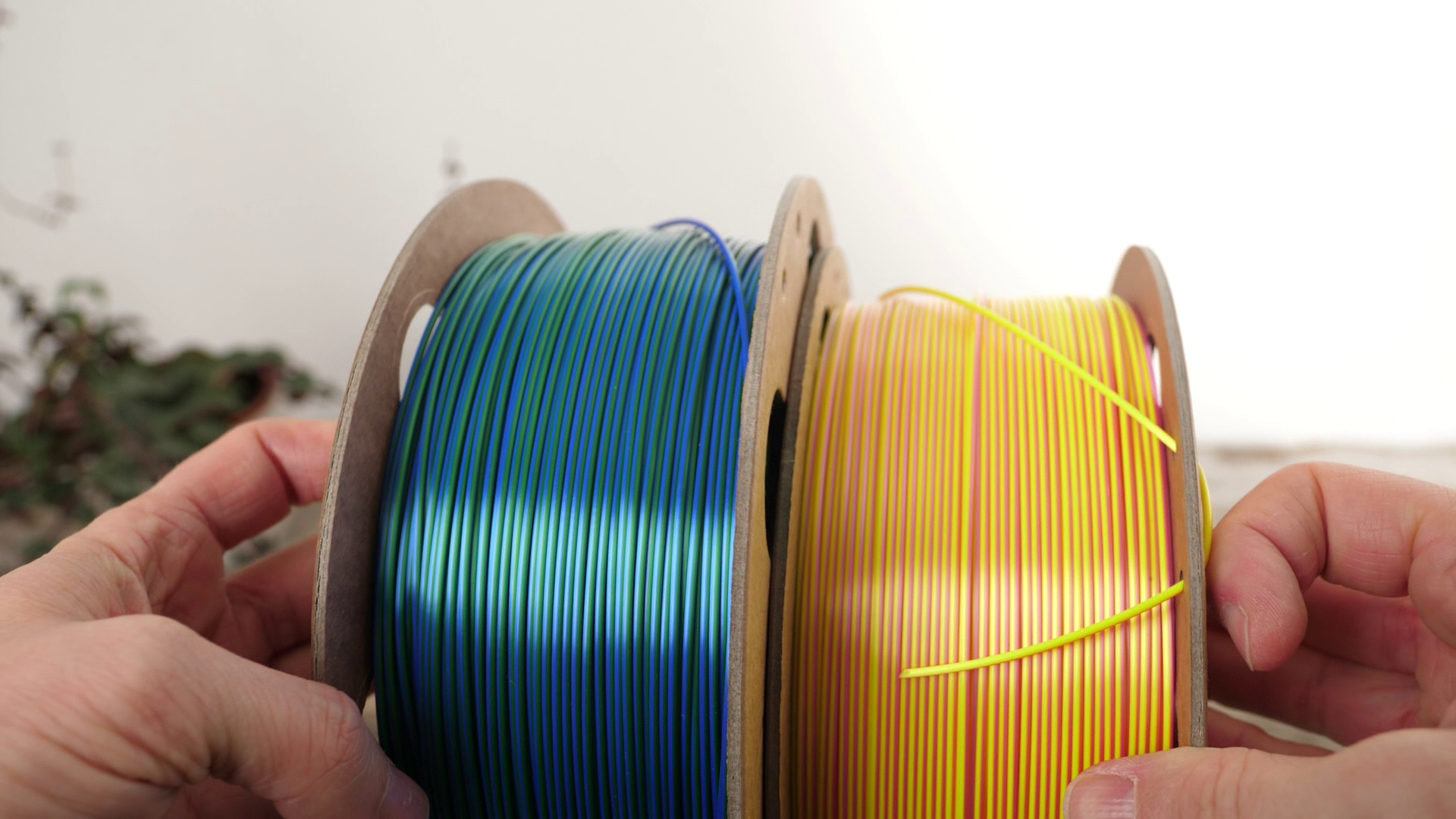

I’m usually not the person that shows you the latest super colorful filament, though when the first spool of this stuff landed at my doorstep, I was really intrigued. Robert, who runs RedLine Filaments here in Germany, sent me a message and teased that he’s going to send me something he’s sure I will be trying out right when I get it into my hands. Of course, I was somehow hoping for a cool new toy and was a bit surprised when I only saw two spools of filament. But this filament was different to anything I’ve ever seen available commercially.

Dual Color Filament on the spools

Over the last few years, we’ve seen quite an advance from standard colored filaments to polymers that have a really unique appearance. There is matte, glitter, silk filament, and special materials that change color depending on the angle you look at them. Then, there are the gradient or rainbow filaments where manufacturers gradually change the pigments added to the extruder to transition from one to another color but, depending on the size of your part, might not even show up properly.

Section cut of the filament

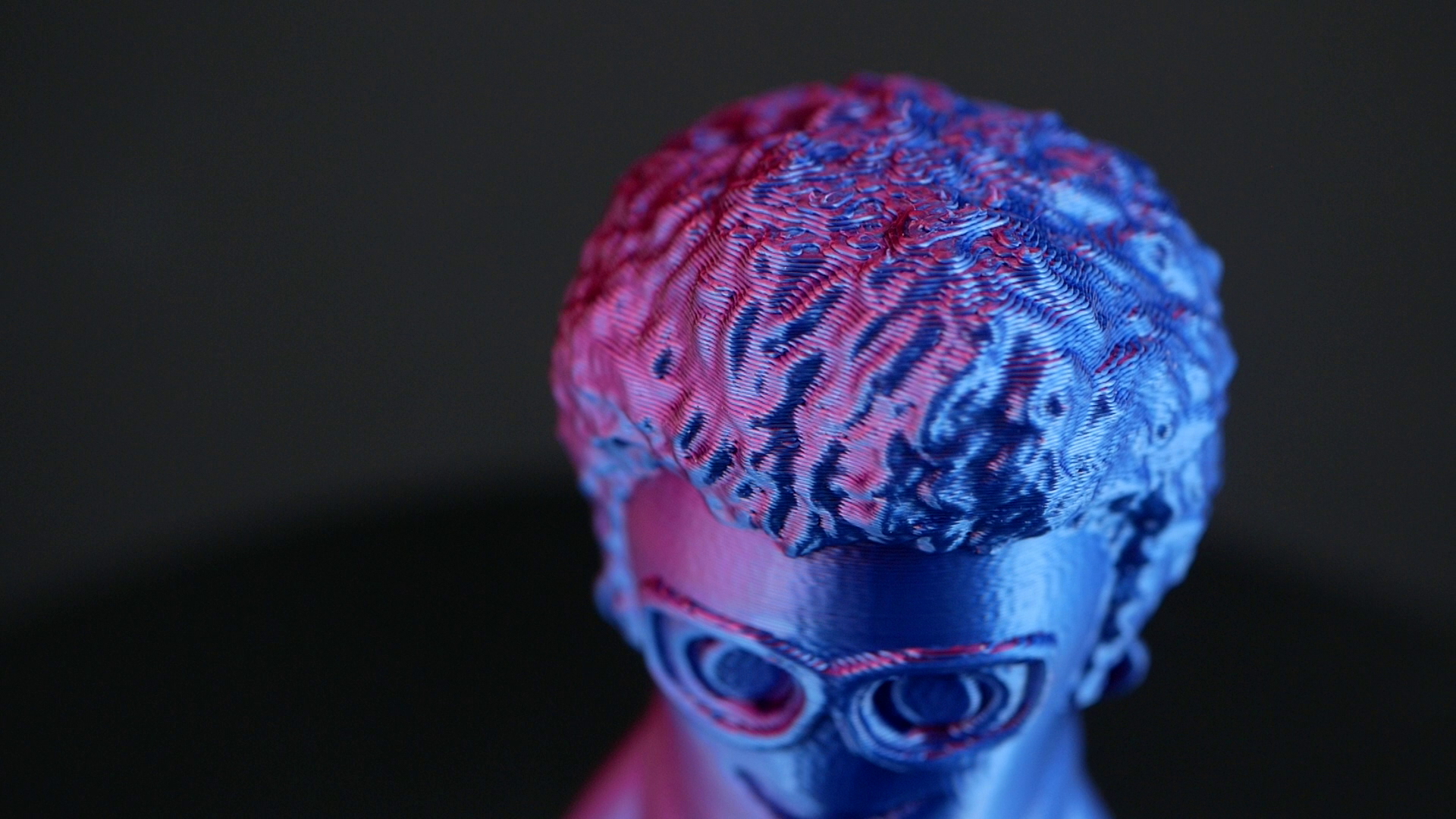

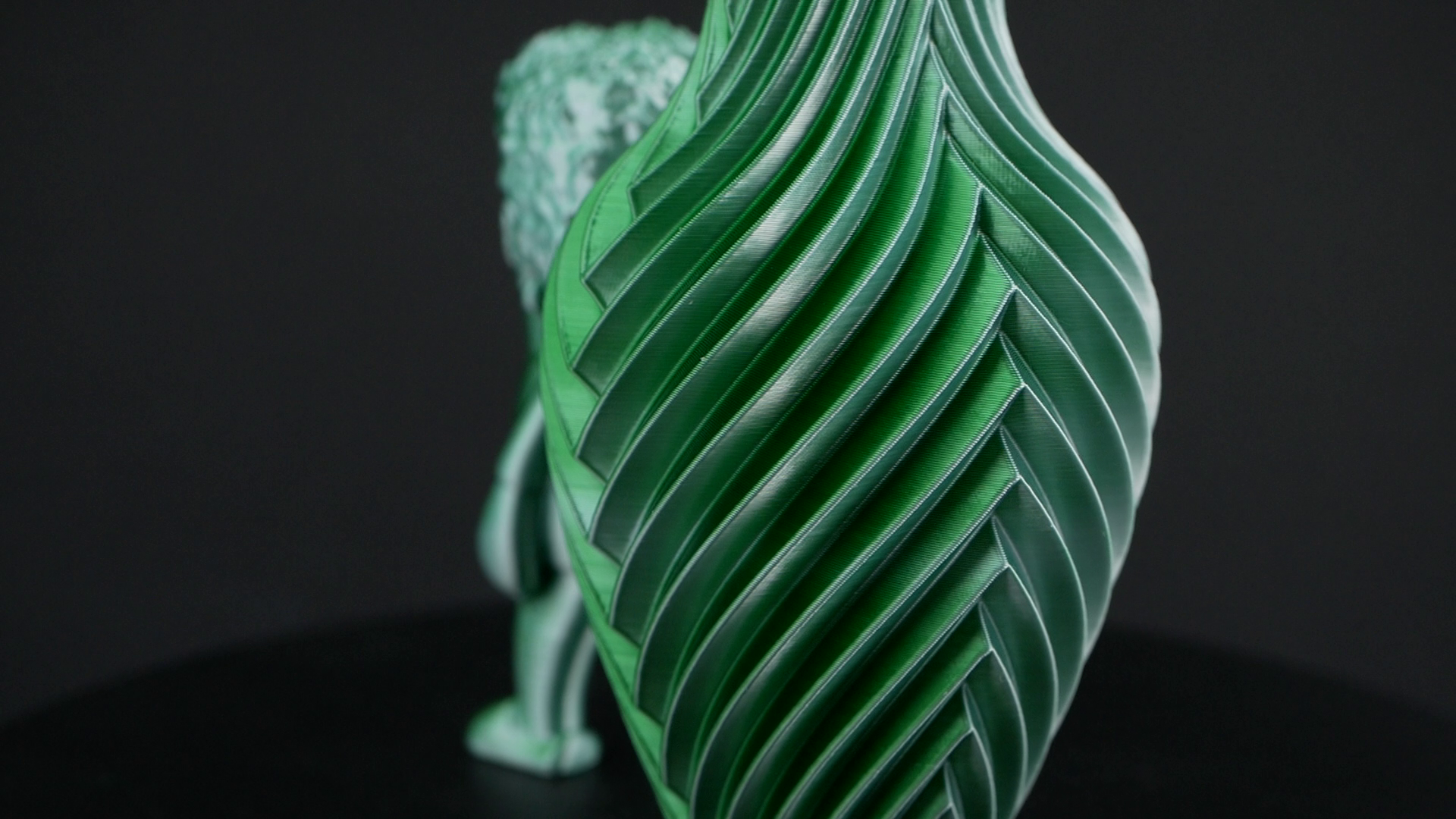

This new filament is different. Redline calls it Mystic Silky PLA, 3DJake magicPLA, and I’ve even seen it popping up on Matterhackers as Quantum PLA, with a vast range of different color combinations. I left affiliate links to some vendors down in the description if you want to check them out! Taking a close look at it, we can see that the filament strand is made from two distinct colors. They are not mixed together, but one half is purely one color, and the other is a different one. If you have a standard hotend, the filament flows through the whole extrusion path in a laminar way, which means no mixing action is happening. This results that the material that comes out of the nozzle is not a mixture of both, but it still has the same two-color pattern as on the spool. If you then print with this material, you end up with parts that have different colors depending on the orientation of the outer faces, which can look really beautiful.

Some available color combinations

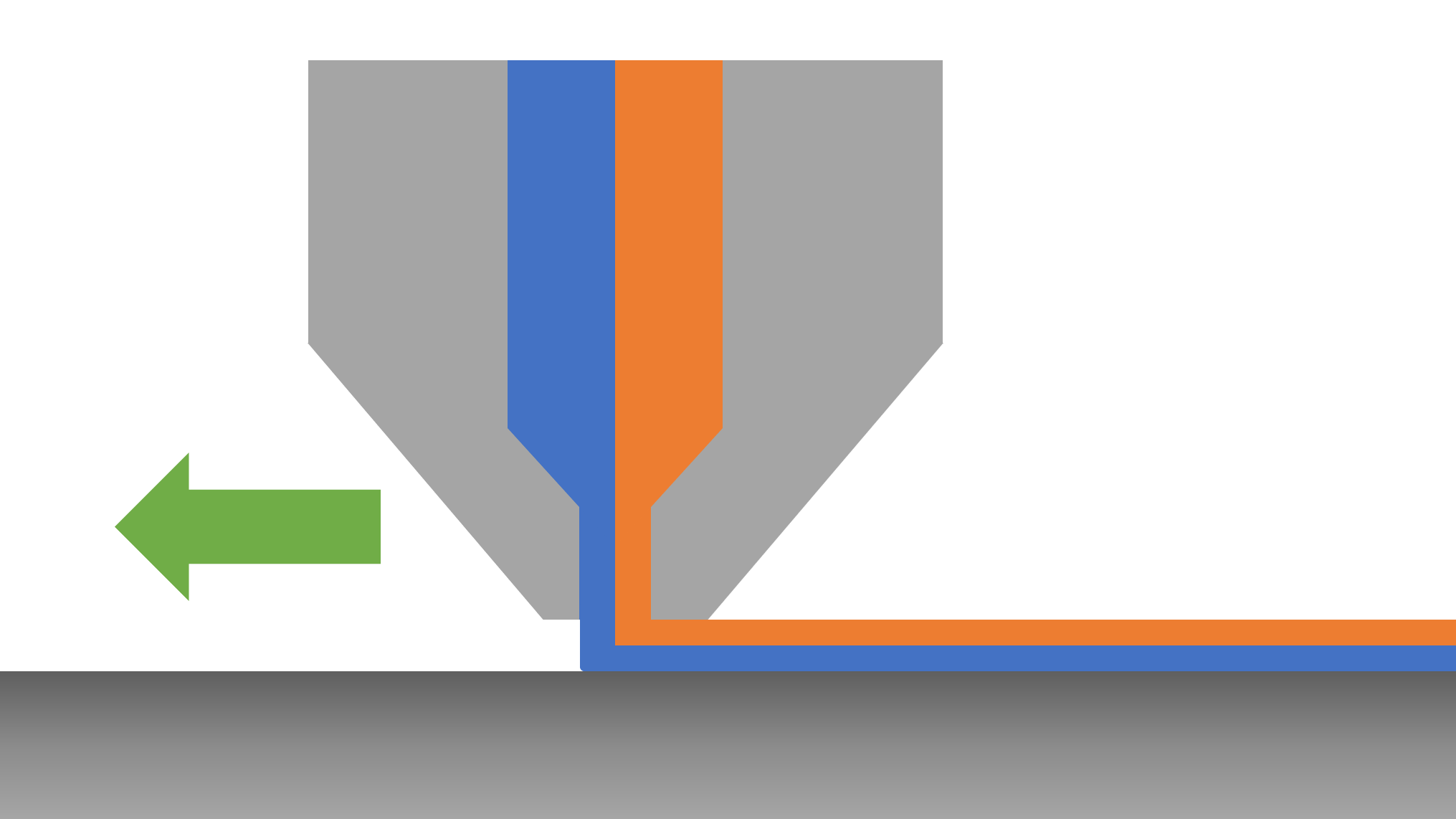

We haven’t seen anything like that before because making such a filament requires special equipment. Conventional color-changing filaments can be made with a standard filament extruder where you just add special pigments. This dual-color, di-chromatic filament is made by co-extrusion. Co-extrusion is something I’m sure you’re very familiar with – let me show you! Have you ever used toothpaste? The different colors here are produced by co-extrusion, which means that different colored substances are extruded next to each other so that they don’t mix.

Toothpaste

For filament making, this is pretty similar. Here, you need, well, only two extruders that feed their molten polymer into a nozzle where they meet up. If you set up everything correctly, the materials don’t mix, and you have a result that’s 50% one color and 50% another color. This is nothing new in the industry and is used with even way more colors and even different materials on very common products. Ever used some fancy-looking trimmer line? Co-extrusion! Pipes, hoses, wires? Co-extrusion! Filled sausages? Co-extrusion!

Co-Extrusion with two extruders and one die

Two-color filament for 3D printing and noticing that the colors don’t mix might even go back on an idea from SunShine, where he made dual-color filament himself by 3D printing his own filament where the lower part was one color and the upper part was another one. This is now just the commercialization of this concept. I even think that if you ever used one of the multiple filaments in one nozzle out hotends, you have ended up with a kind of similar printing effect.

YouTube user SunShine demonstrating this technique in 2019

So when printing this material, you end up with different effects on outer walls and upper and lower surfaces. If we print a simple circle, the two colors should come out in a very similar orientation to the filament that went into the feeder. This results that color one is on the outside on one side, where we can see it; on the other side, it’s color two. In-between, there is a transition.

Circular Extrusion

The transition area is really interesting as well, because we just only looked at the color difference in the XY plane. In the transition zone also the stack-up of the layers changes. Depending on the direction in which you’re printing, one or the other color is on top. This leads to the stripe pattern on top surfaces due to the forth and back motion of the infill.

This is all theory, though if you’re interested in that stuff, a fascinating one. In practice, it’s not that important, and parts sliced with standard-settings come out with a nice and even color transition, and the silky nature of the filament gives it that even more mystic touch. Vase more prints look the best, just because of the continuous nature of the printing motion and that the spiral always goes into the same direction, but even regular parts come out great. Though maybe if something looks off, take a look at the printing direction of your perimeters. I do have the impression that slicers try to go either only clockwise or anti-clockwise, but if they don’t, color stack-up will vary and, therefore, also the evenness of the effect. I didn’t print with a lot of silk filament in the past. Still, I had the impression that this dichromatic material came with the same challenges of higher printing temperatures and weird melt behavior that can lead to quality problems, but I had no issues getting it to work on all of my machines. And just to mention it – silk PLA filaments are not great when it comes to mechanical properties, so rather use this material primarily for its visual appearance.

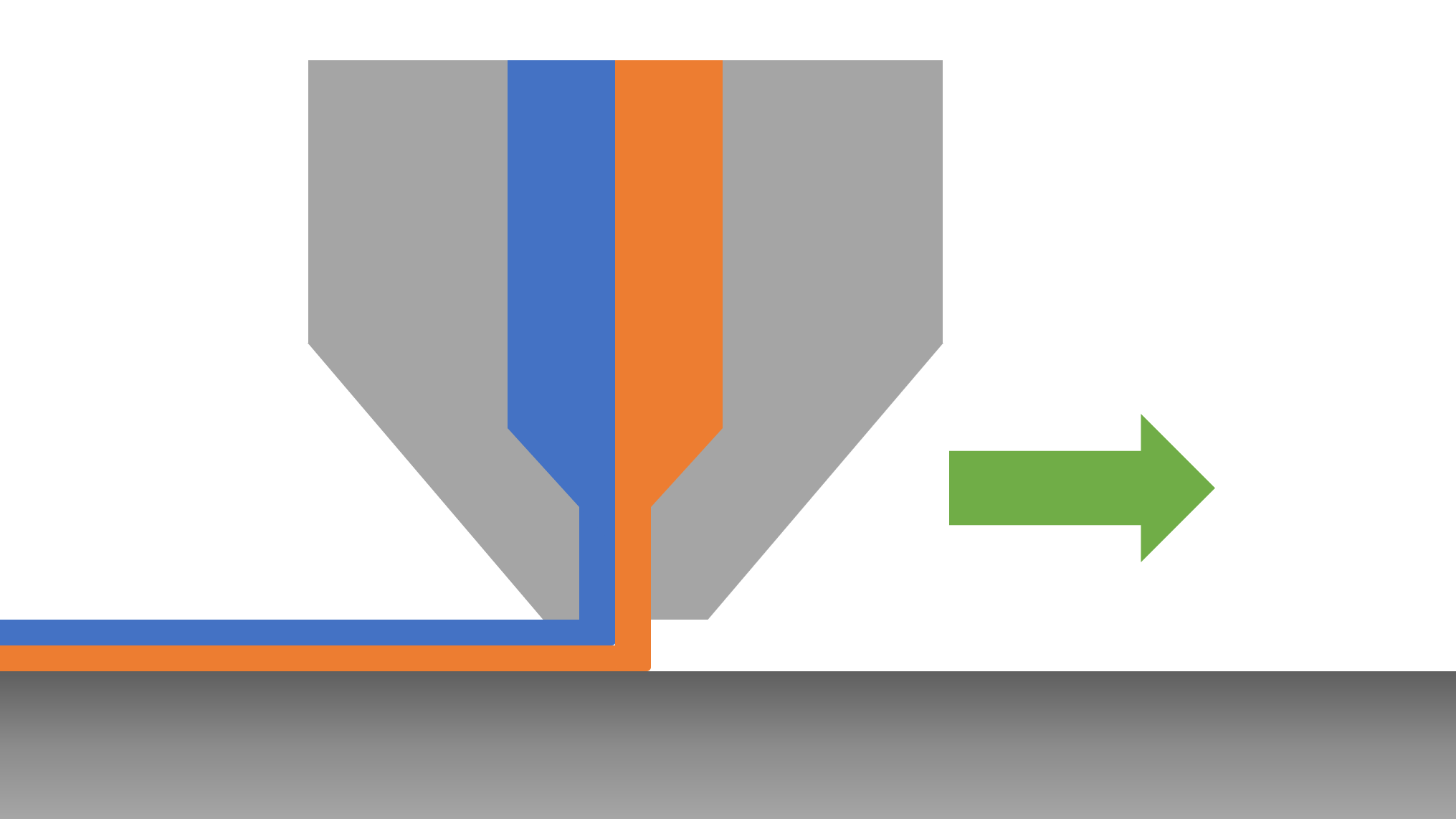

Right at the beginning, I mentioned that this method of manufacturing filament might open up great opportunities for new functional materials! Maybe you remember my PC-core ABS filament that I printed on my E3D Toolchanger. This material had a hull of ABS and a polycarbonate core and retained that composition even when it was extruded. This material took advantage of the two different softening points of ABS and PC so you could anneal parts at temperatures suitable for ABS, where the polycarbonate core still remained rigid and eliminated the warping of the parts. I was only able to manufacture this material on a very small scale and in an inconsistent manner because no filament manufacturers had co-extrusion machines. Now that these dichromatic materials manufactured on co-extrusion machines are available, extrusion plants only need to switch out the die to extrude one material on the outside of another one instead of next to it. This opens the possibility to explore a range of really exciting and affordable multi-material filaments that could advance the FDM 3D printing technology a significant step forward!

Co-Extrusion with concentric die

So what’s your take on this new type of filament? Also, let me also know your favorite color combination down in the comments! Is it green and white? Deep Space? Blue and green? Frozen Gold? Pink and purple? Sunset Sky? Pink and yellow or aluminum and raspberry? If you’re asking me, my favorites are deep space and sunset sky! Maybe you don’t really care about colorful materials and just want to see functional materials soon!

Check out the Dual-Color Filament Deals (Affiliate)

Mystic Silky by Redline Filament (GERMANY)

magicPLA by 3DJake (EUROPE)

Quantum PLA by Matterhackers (USA)