What's STRONGER - 3D Prints or Wood?!

I’m currently moving into a new and actually my first real studio, for which I had to build a bunch of benches and things like a filament rack. Wood has always been the material of choice for me because it’s easy to machine and is still very strong if you use it properly. This is why my first CNC router was made from wood, and even many of my test machines still are. Unfortunately, wood prices and availability are a bit insane at the moment, so you usually take what you can get and afford. But can you for example replace expensive multiplex plywood with particle board? I’ve been asking myself for ages how the strength of different types of wood, particle, and fiberboards compare and how these materials would also stack up against common 3D printing materials. That’s why I tested a ton of samples to find out how the bending strength and, of course, the “hook strength” compare to each other.

Test samples

The first material is simple spruce wood with an average density of 0.4 g/cm³. We most commonly use this softwood here in Germany as construction lumber.

Spruce Wood

Since we’ll also take a look at the strength and stiffness per weight I also had to include super lightweight balsa wood where my samples had an average density of 0.17 g/cm³.

Balsa Wood

Mechanically speaking - natural wood is, in a way a bit similar to 3D prints, because it has a weak and a strong axis. Wood is strong along its fiber direction but can be quite weak perpendicular to it just like 3D prints are strong in the print plane but weak between the layers. This is something that is very important to keep in mind when designing parts. I loaded the parts only along their dominant axis for all the tests in this video to keep it simple and not overwhelm you with data. If you are interested in wood layer adhesion strength - let me know, and maybe I can do more tests!

Next, I included Birch Multiplex Plywood, a material I used a ton in the past when I required high-strength parts. Plywood is made from layers of wood veneer that are stacked and glued with a 90° difference in fiber orientation onto each other. This gives Multiplex quite similar strength properties in all loading directions within the plane. My multiplex board had an average density of 0.68 g/cm³.

Multiplex Plywood

I also included three different types of particleboard. First MDF - which means “medium-density fiberboard”. For this material, wood is broken down into tiny fibers that are then pressed to sheets using heat and a resin binder. The MDF I bought had an average density of 0.76 g/cm³ and was, therefore, the heaviest of the wood materials.

MDF

Next, I got some particle board that is in a way quite similar to MDF, only that the particles are considerably bigger. The boards are often made with finer particles on the outer layers and coarser ones on the inside to improve the surface finish and strength of the material. My particle board had an average density of 0.66 g/cm³.

Particle Board

Finally, I included OSB which means “oriented strand board”. I used this as a surface for my printer desks because I assumed it’s quite strong but still reasonably priced and has this distinct look I kind of like. On OSB, strips of wood are bonded together with some alignment of the wood along the axis of the boards. The sheet I bought had an average density of 0.69 g/cm³.

OSB

As the two most common 3D printing materials, I chose PLA and PETG, both from dasFilament, with an average density of 1.2 g/cm³ when printed with 100% infill. Since printing with that much infill is something I rarely do, I also included parts with 30% infill and 3 perimeters which is a setting I often use for mechanically loaded parts. These had a density of around 0.8 g/cm³, so more in the range of the wood samples. I printed the parts on my Prusa MK3 and the crazy fast Bambu Lab X1.

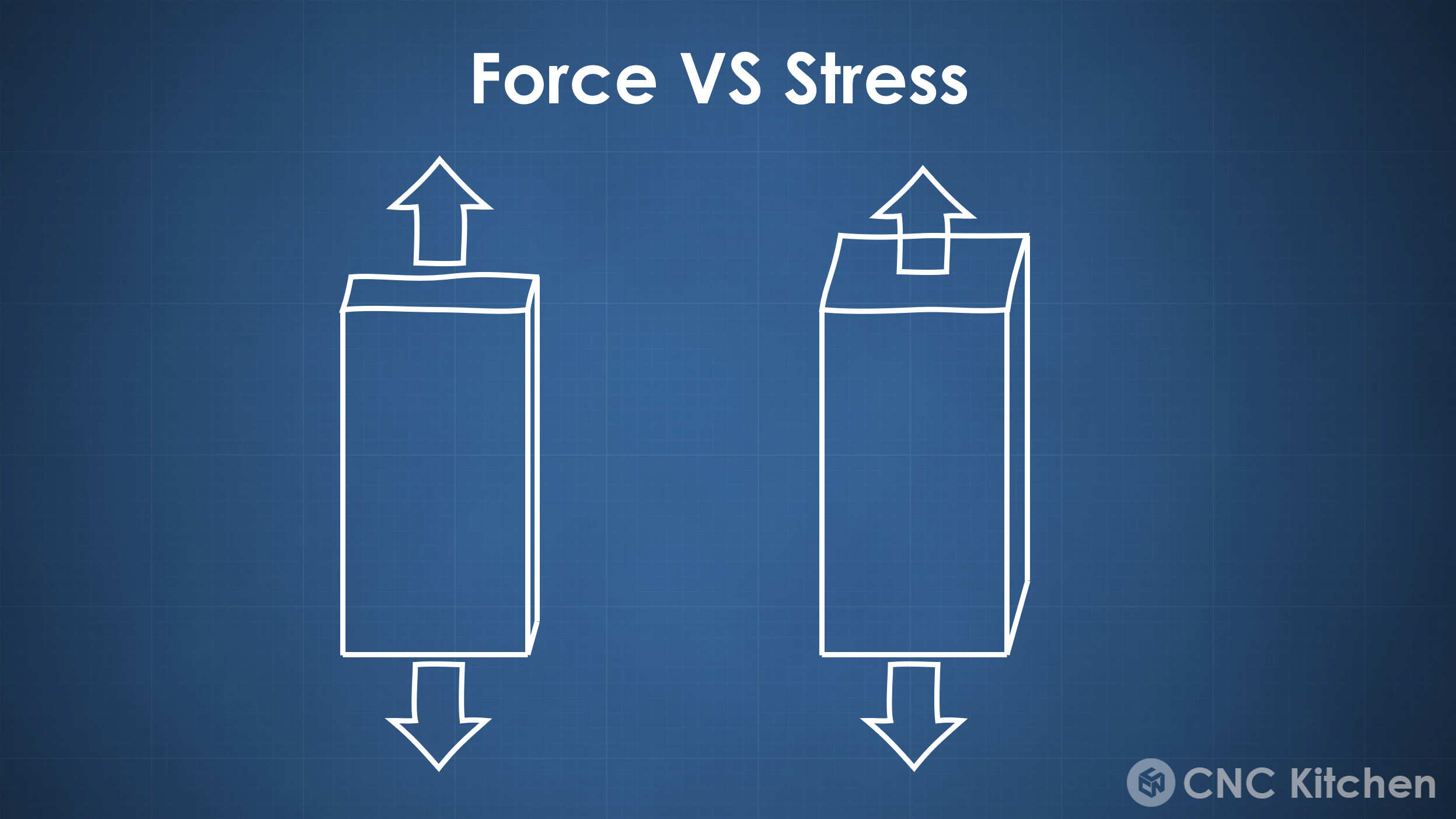

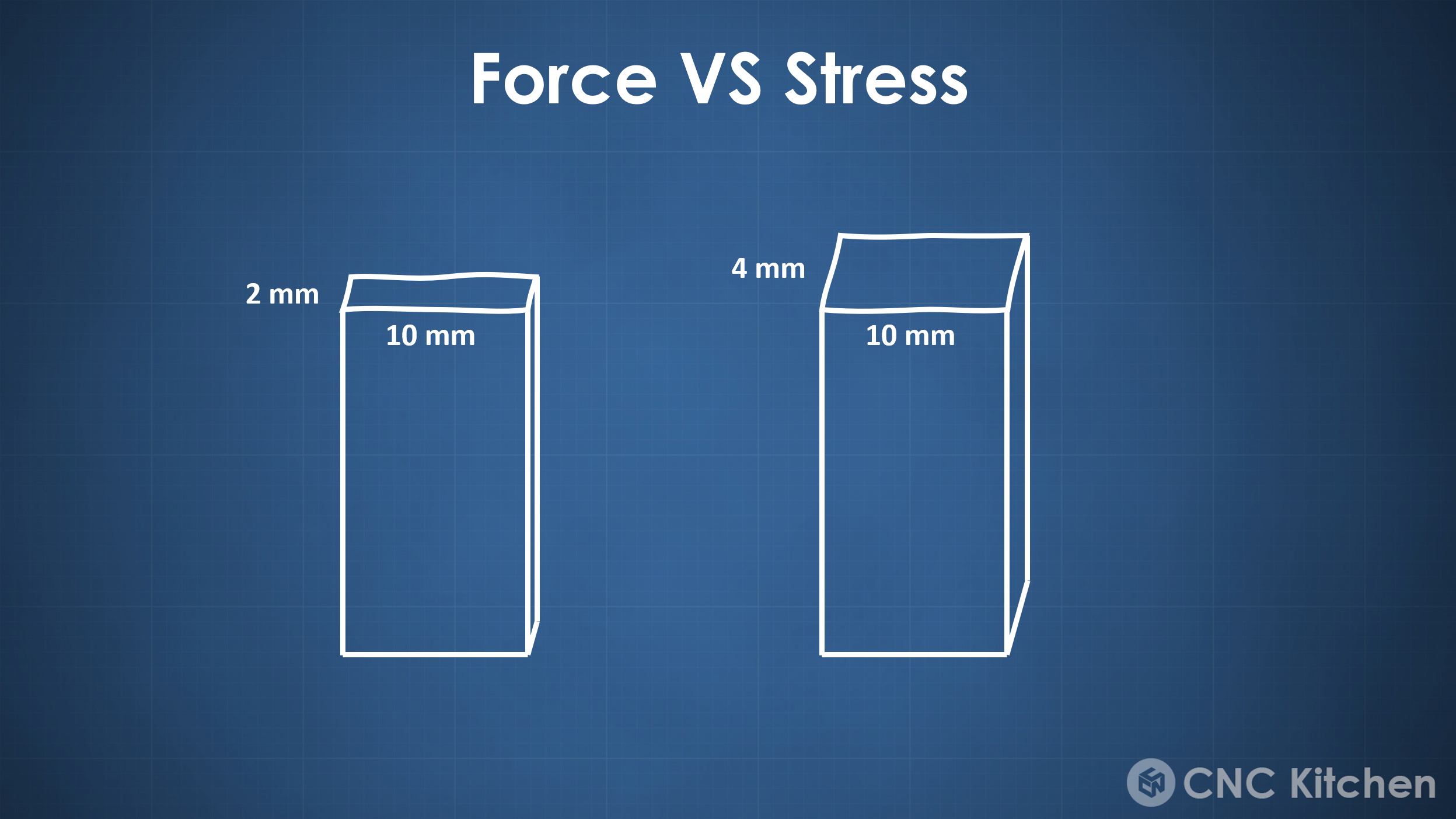

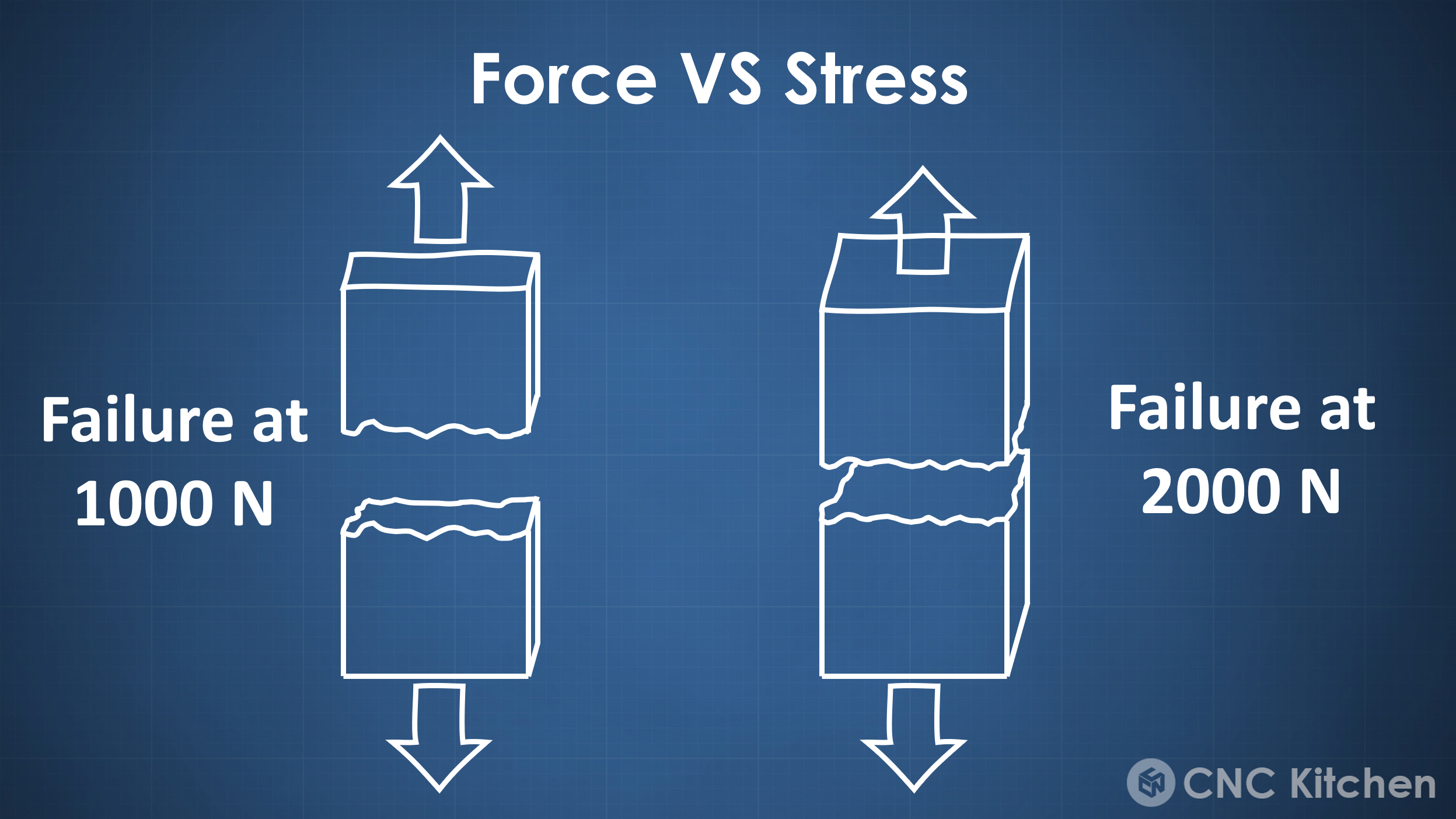

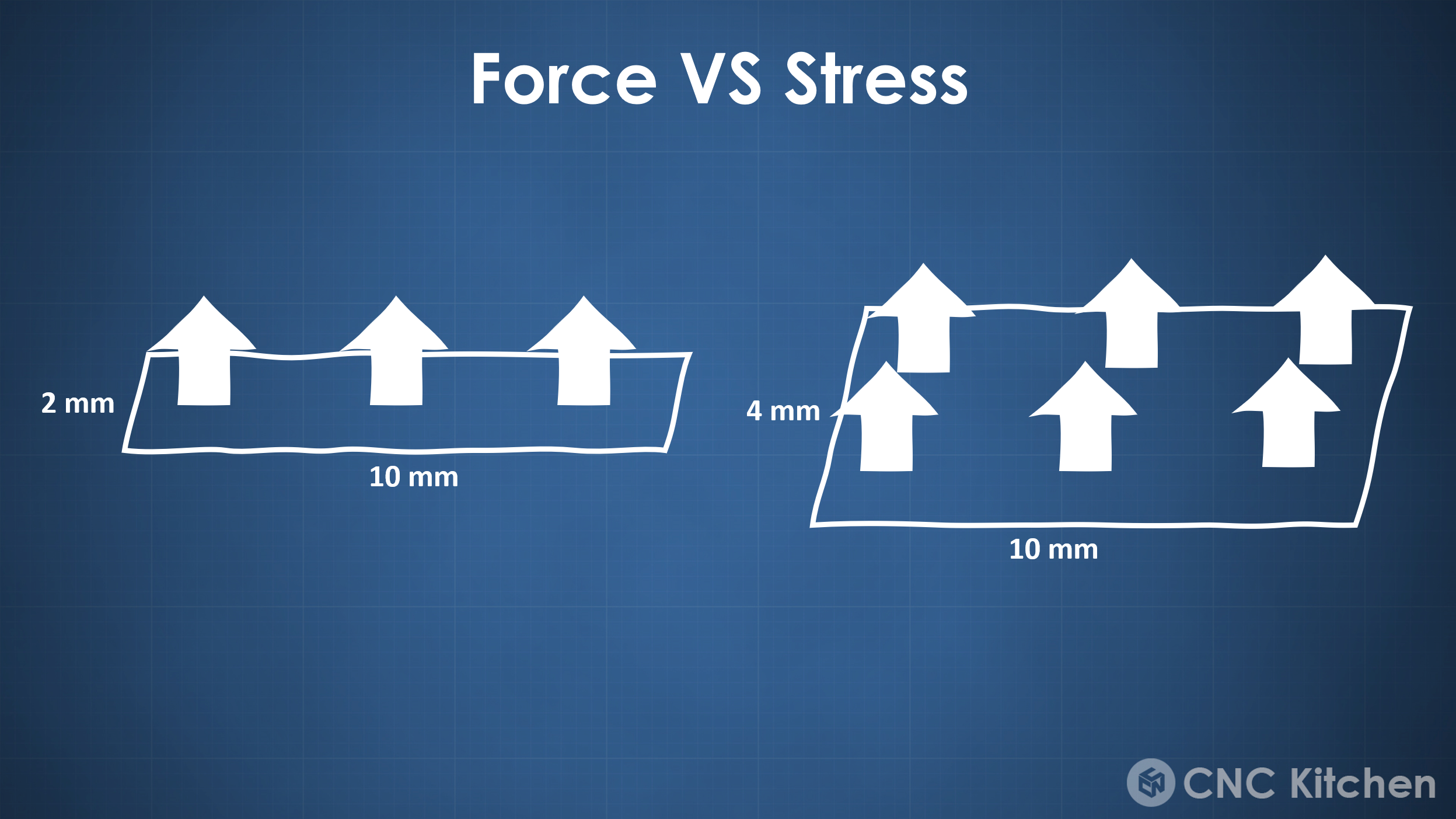

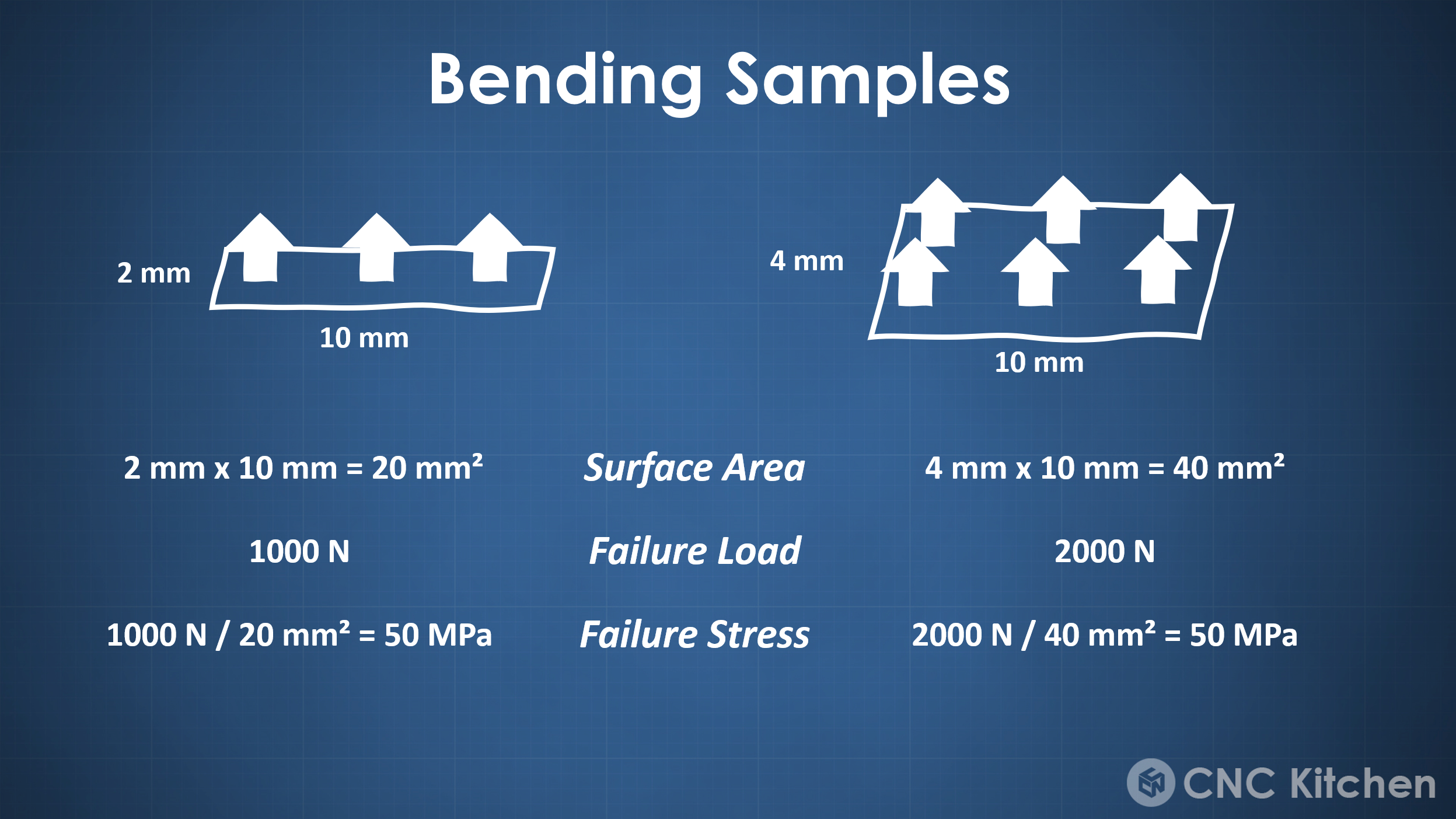

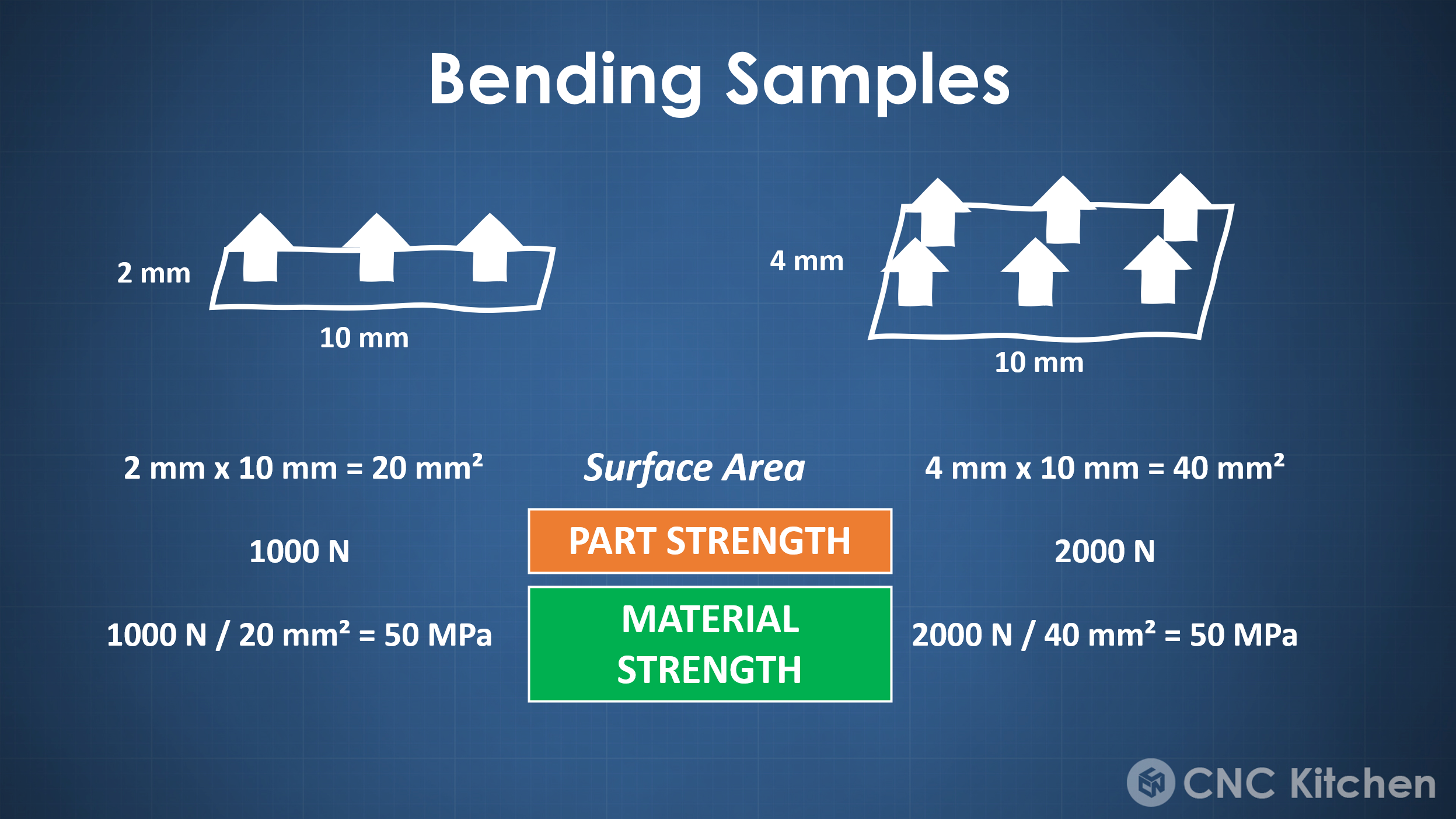

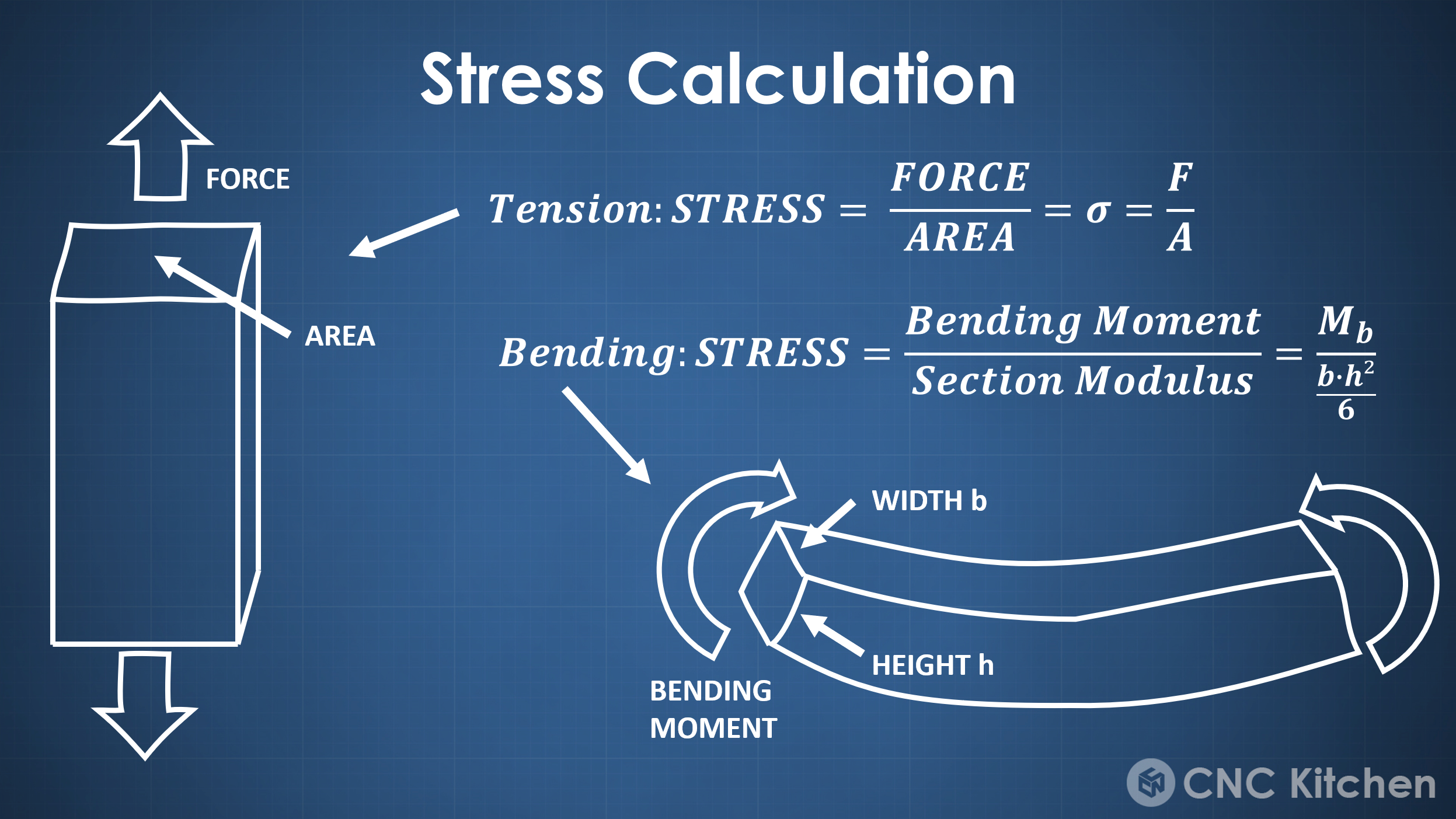

Let’s start with the bending test, which is a common investigation done on wood materials and sheets. Due to the availability of materials and the capability of my test machine, I used bending bars with a cross-section of 9x9 mm that span over 135 mm on the test machine. They will get loaded until they either fail or we can see a decline in force due to severe plastic deformation. The result of this test will be the maximum bending stress, and using the stress/displacement plot, we can also get an idea of the material’s stiffness. The reason why I’ll show bending stress instead of simply the force is not that I think I’m fancy. There is another very simple but not always obvious reason. Let’s look at this example and pull two bars of the same material until they break. One has double the thickness, so double the characteristic surface area. The thicker one will break at twice the load because it has twice the material to distribute the force. Does that mean the material in the thicker bar is stronger? No! It only uses more material. This is why we use stress instead of force in engineering to characterize a material. The stress is the force divided by the characteristic surface area.

Bending Test Setup

In metric units, we use MPa, where one MPa is one N per mm². In imperial units, psi is often used, which is pounds per square inch. 1 MPa is around 145 psi, by the way. This approach is very important because all the samples slightly vary in dimensions. Otherwise, parts that are slightly thicker due to their tolerances would have an unfair advantage, and we couldn’t compare the results objectively. On these bending bars, the stress is not calculated by force divided by area but by bending moment divided by the section modulus. Here the thickness of the bar is even squared, so a slight deviation in geometry between the samples would make the results even less comparable if we would not use that approach! And this is why stress makes more sense than force!

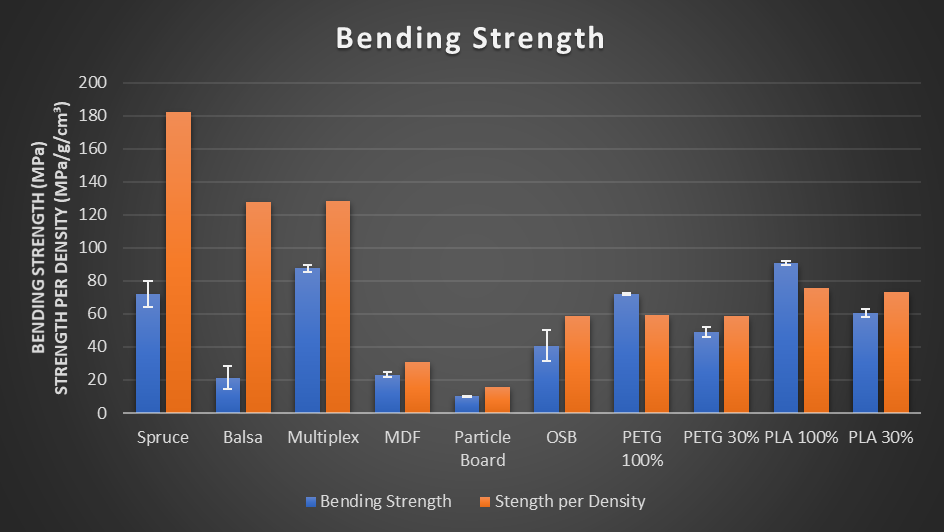

Now to the tests! The spruce wood was already quite strong, and the samples failed on average at 72 MPa of bending stress. The failure announced itself by a bit of crackling before the first major break came. Even though the balsa wood specimens broke in quite a similar fashion, their average strength was only 21 MPa, and the stiffness was also significantly lower. The Multiplex sample was the strongest so far and snapped at a considerable 88 MPa. The MDF bending bar - even though four times heavier than Balsa wood was only a tiny bit stronger than the natural wood and broke at 23 MPa. The particleboard was the weakest on average, and the samples broke at only 10 MPa. Most of them didn’t even fail at the center section that’s loaded the most but broke at a defect next to it. So definitely no material for high load-bearing applications.

Off-center Failure

On the other hand, OSB was quite strong, and the samples failed at 41 MPa on average and not in the center but at a weak section next to it. Let’s now continue with the 3D printed samples. On average, the fully dense PETG bars failed at 72 MPa, though they didn’t break and only yielded. The samples with only 30% infill obviously were weaker and only able to withstand 49 MPa. The PLA samples with 100% infill were the strongest, and they failed on average at 91 MPa. The samples flexed quite a bit before they broke due to the rather brittle nature of PLA. The 30% sample could still bear 61 MPa on average before failure.

Bending Strength of the Samples

In the end, PLA was the strongest, followed by Multiplex, and the simple particle board was the weakest. Also scatter on the results was generally a bit higher on the wood or the wood-based materials because of the natural variance of the materials. If we calculate the strength per weight, the results change significantly, especially the 3D printed parts falling way behind. Here, the simple spruce wood takes the lead, followed by balsa and Multiplex. This shows why these materials have been used in the past, even for airplane construction. These natural materials are very strong for their weight. Looking at the stiffness shows this even more! I would not have expected that the lightweight wood samples would be so stiff compared to polymers. Spruce-wood and Multiplex were more than twice as stiff as PLA or PETG. The super lightweight balsawood was almost as stiff as fully dense PETG. Calculating the density by weight even increases the advantage of the natural woods. The engineered materials - polymers and particle materials- rather decrease in performance though show less scatter in the properties - which makes them more predictable and usually have more uniform properties.

Bending Strength per Density

So this was how all the tested materials performed in bending, but how do they fare in a more realistic yet less scientific load case, like my test hook? In the bending test, we had a pure bending load with tension on the lower side and compression on the other. The hook is mainly in tension with a bit of a gradient due to the bending moment. For this, I again printed hooks with 100% and 30% infill on the Prusa and the BambuLab X1. All the wood samples were machined on my Mekanika EVO CNC router. I aligned the parts and the wood so that the strong axis of the wood aligns with the critical section on the hook. The challenge here was that I had to machine the samples from both sides to add even chamfers on the whole circumference. For both-sided machining, it’s super important that the axes of the CNC are square because otherwise, the machining operations don’t line up.

To achieve that, I routed rectangles into the spoil board and measured the distance of opposite corners. At first, the distances didn’t match, but with some simple trigonometry, I was able to determine how much I had to adjust the end-stops on the axis of the MEKANIKA router to make sure they matched in the end. First, I faced the top of the wood sheets to make sure they were 9 mm thick, pocketed out the inside of the hook, and machined it on the outer perimeter, leaving some tabs, so the hooks were securely held in place. Then I machined the chamfer on the first side with a simple 45° tapered cutter. When machining from both sides, the challenge is to position and align the part down to a tenth of a mm or less. There are several ways to do that. I tend to use dowel pins for that. So during the front machining operation, I already machined two holes, one is at the origin of the machining coordinate system, and the other is 300 mm down the x-axis. After machining the first side, I also machined these holes into the waste board and inserted dowel pins. I turned my part around and positioned and aligned it with the pins. This way, I can use the holes as a reference for the second operation and perfectly machine the chamfers on the second side. I cut the tabs with a saw blade and finished the sides with a belt sander. The results were really beautiful are highlighted the grain structure of the woods nicely. The balsa parts were a little hairy since the cutter was already a bit dull in the end and rather made for metals and not wood. But let me know down in the comments which hook you like the most!

Machined Samples

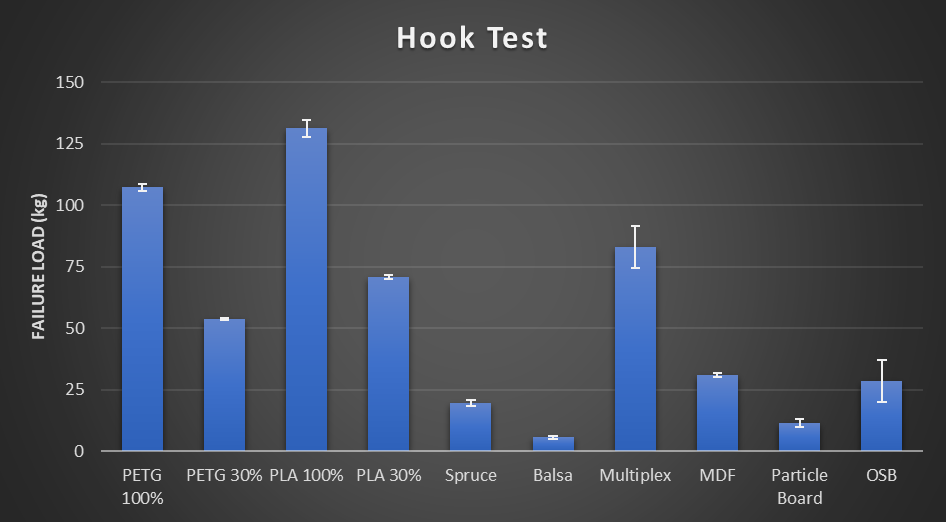

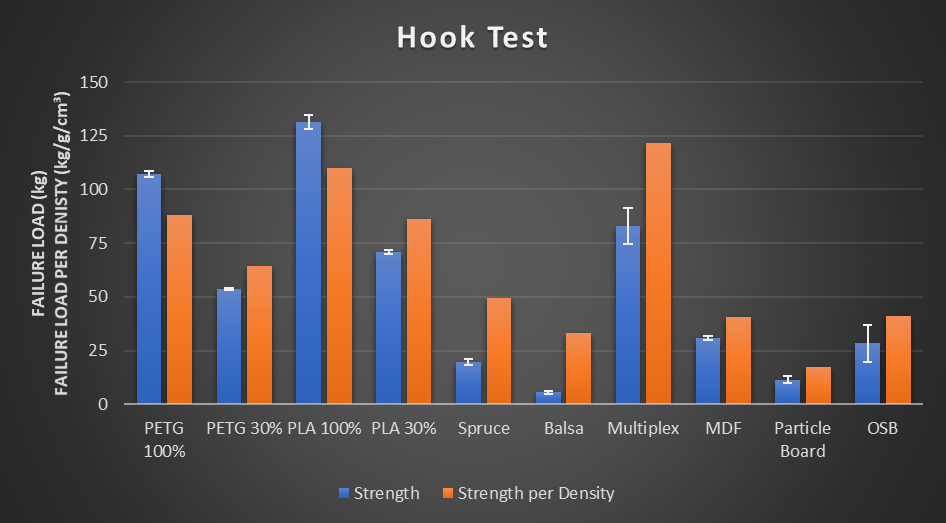

Let’s start with the tests of the 3D printed parts. The hook is less scientific than the bar sample but will still delivered very insightful results! The PETG part with 100% infill failed at 110 kg of load and broke quite violently. The 30% infill parts were only able to bear half the load and failed at 54 kg on average but just yielded. PLA was even stronger, and the fully dense parts broke at a staggering 131 kg. The parts with 30% infill still were able to take 71 kg on average. The spruce wood parts didn’t perform as well as I would have expected after the stiffness test - not because they were generally weaker, but the machining orientation led to a shear failure at the lug, while the section under test was probably still mostly untouched. This way, the spruce wood hooks could only bear 20 kg of load before they broke. Balsa was very similar and also failed at a different location with only 6 kg of average failure load. The different orientations of the fibers in the Multiplex, on the other hand, led to quite remarkable results, and the parts were able to handle 83 kg on average though they still failed at a different location than predicted. The baked-together fiber cake of the MDF board did exactly what you would expect and produced quite homogeneous material properties in all directions. With 31 kg of failure load, the parts weren’t that strong, but they broke where one would expect. The particleboard that also doesn’t have a dominant fiber direction behaved similarly predictable but was super weak with only 11 kg of failure load. The long fibers of the OSB reinforced the part a little, but the random nature of it made the point of failure a bit unpredictable again and resulted in an average failure load of 29 kg with significant scatter.

Hook Strength

The exciting part is the strength per weight, where the wood materials again significantly improve their performance, and Multiplex Plywood can even supersede the 3D prints. The natural woods still lack a bit behind, but only because they are hard to use for such a complex part due to the anisotropic nature of their properties.

Hook Strength per Density

So, in the end, I was quite impressed by the results of the samples. First, I would not have expected that wood, especially Spruce and Balsa, is so stiff and strong compared to the two simple polymers I’ve tested, especially if you also consider their weight. This is a reason why they are used so much in construction and even in aircrafts - if applied properly. The test hook results showed this. If you don’t align or choose the right material for your application and it’s not loaded properly, it can fail way earlier than expected. Plywood, especially high-quality Multiplex, gives you the best of both worlds—relatively low weight but superb stiffness and strength, with less dependence on orientation. Particle, chip, or fiberboard didn’t really shine and should primarily be used as a filler or if strength is not essential. The 3D prints from PLA and PETG were great in strength but lacked stiffness and are not very well suitable for lightweight applications if you don’t properly tune infill and perimeters. On the other hand, the results didn’t scatter a lot, making them easier to predict and size for certain applications. But what’s your opinion on these results? Would you have expected a similar outcome, and would you like to see more types of materials and orientations tested?

Equipment used in this video

MEKANIKA EVO CNC Router: https://www.mekanika.io/shop/evo-3545?category=3#attr=

Bambu Lab X1: https://www.kickstarter.com/projects/bambulab/bambu-lab-x1-corexy-color-3d-printer-with-lidar-and-ai

Prusa MK3: https://geni.us/CNCKPrusa

dasFilament PLA & PETG: https://geni.us/DasFilament